When we open a fresh pack of cigarettes, the first thing that often catches our eye is that shiny silver or gold paper. While it appears simple, it is engineered with more technology and functionality than one might expect. This is no ordinary wrapping paper; it is a precisely designed key component—the Cigarette Inner Liner. It plays a vital “guardian” role within the entire Tobacco Packaging ecosystem.

Core Materials: A Fusion of Aluminum Foil and Technology

The core value of the cigarette inner liner lies in its superior material composition. The most traditional material is Aluminum Foil Paper for Cigarettes, a composite material created by bonding an extremely thin layer of aluminum foil to paper through a process called lamination. This structure gives the inner liner its excellent physical properties.

As technology has advanced, a more cost-effective alternative has emerged: Metallized Paper (VMPET Paper). This involves vapor-depositing a micro-thin layer of aluminum onto the paper’s surface. While it isn’t solid aluminum foil, it provides excellent protective qualities and a similar metallic sheen.

Key Functions: Locking in Flavor, Guarding Quality

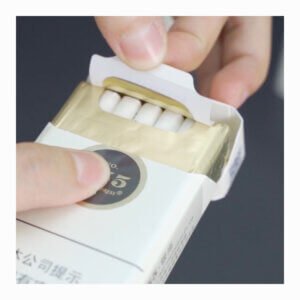

As prominently featured on the packaging in the image with the words “TASTE GUARD,” the primary mission of the inner liner is Aroma Preservation and ensuring a Flavor Lock. The unique flavor of tobacco is highly susceptible to degradation from environmental factors. The inner liner provides the perfect solution thanks to its excellent Barrier Properties.

Moisture-Proof: The foil layer is an outstanding Humidity Barrier, effectively preventing external moisture from getting in while retaining the necessary moisture within the tobacco itself. This prevents the tobacco from becoming too dry or too damp, thus preserving the smoking experience.

Aroma Preservation: It effectively stops the volatile aroma compounds in the tobacco from escaping, ensuring that the consumer enjoys the freshest and most authentic flavor upon opening the pack.

Light-Proof: Light, especially ultraviolet (UV) rays, can accelerate the oxidation and deterioration of tobacco. The opaque foil layer completely blocks light, achieving effective Freshness Preservation.

From Roll to Product: A Journey of Precision Manufacturing

On the production line, these inner liners exist as massive rolls of Packaging Roll / Rollstock. According to brand specifications, this rollstock goes through a high-precision printing process, where brand logos (like the “U²” in the image), functional claims, and other information are applied, turning it into Printed Foil.

Subsequently, this printed foil is fed into high-speed packaging machines, where it is precisely cut, folded, and formed before being inserted into the cigarette packs. This transforms it from a flat raw material into the three-dimensional Finished Product we see. This entire process is a showcase of the technological capabilities within the Flexible Packaging industry.

สรุป

In conclusion, a small piece of Cigarette Inner Liner is far more than a simple decorative element. It is a fusion of material science, printing technology, and precision manufacturing, acting as a silent guardian that ensures the tobacco product maintains its optimal quality from the factory to the consumer. The next time you see one, perhaps you will have a greater appreciation for the technology and craftsmanship behind it.