Customized Printing Anti-Counterfeiting Technologies: Holographic Hot Stamping, Security Patterns, Watermarks, and Ultraviolet Fluorescence (UV)

导言

In the realm of brand protection, product security, and anti-counterfeiting verification, customized printing anti-counterfeiting technologies are highly valued for their uniqueness, high security, and flexibility. Holographic hot stamping, security patterns, watermarks, and ultraviolet fluorescence (UV) anti-counterfeiting are four widely used and effective techniques. These technologies, combined with customized design and high-precision printing processes, provide personalized, high-security anti-counterfeiting solutions for brands and products. This article explores the principles, customization features, and applications of these four technologies in the printing industry.

I. Holographic Hot Stamping

1. Principle

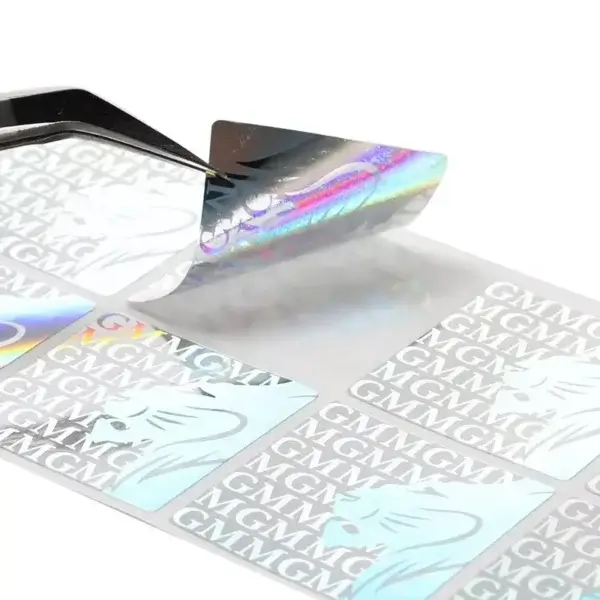

Holographic hot stamping utilizes laser holography and precision stamping techniques to create micro-scale grating structures on substrates, producing dynamic visual effects. Customized printing employs specialized molds and precise alignment to stamp holographic patterns at designated positions, displaying unique color shifts or three-dimensional effects.

2. Customization Features

Personalized Design: Holographic patterns, such as brand logos, text, or specific images, can be tailored to brand requirements.

High-Precision Alignment: Advanced stamping equipment ensures precise alignment of holographic patterns with printed designs, enhancing aesthetics and security.

Versatile Substrates: Supports customization on various materials, including paper, plastic, and metal foil.

3. Applications

Customized holographic hot stamping is widely used in high-end packaging (e.g., cosmetics, alcohol, luxury goods), identification documents, and anti-counterfeiting labels. For example, brands can create dynamic logo-based holographic labels that are both visually appealing and difficult to replicate.

II. Security Patterns

1. Principle

Security patterns are created through high-precision printing, forming intricate lines, micro-text, or hidden designs on material surfaces. These patterns are typically difficult to discern with the naked eye but become visible under magnification or specific lighting, utilizing mathematical algorithms to ensure design uniqueness.

2. Customization Features

Exclusive Patterns: Unique designs, such as brand names, logos, or specific codes, can be created for brands.

Hidden Elements: Micro-text or invisible patterns can be embedded, visible only under specific conditions.

Flexibility: Patterns can be adjusted in complexity and color to suit various product packaging needs.

3. Applications

Customized security patterns are commonly used in tickets, certificates, brand packaging, and anti-counterfeiting labels. For instance, companies can design patterns with micro-scale brand identifiers to enhance packaging security and recognizability.

III. Watermarks

1. Principle

Watermarks are formed during the papermaking process by controlling pulp density or thickness to create specific patterns or text visible under transmitted light. Customized watermarks use specialized molds to embed brand-specific patterns or text into paper, making them difficult to forge.

2. Customization Features

Brand-Specific Designs: Watermarks can feature brand logos, text, or unique graphics.

High Concealment: Invisible under normal lighting, watermarks require transmitted light for verification, ideal for high-security needs.

Process Integration: Can be combined with printing processes to embed watermarks in specific areas.

3. Applications

Customized watermarks are widely used in currency, passports, certificates, and premium packaging paper. For example, luxury brands can use custom watermark paper to elevate product presentation and anti-counterfeiting capabilities.

IV. Ultraviolet Fluorescence (UV) Anti-Counterfeiting

1. Principle

UV fluorescence anti-counterfeiting involves adding special fluorescent inks or materials during printing, which display specific patterns, text, or colors under ultraviolet light. Customized printing allows for tailored fluorescent effects in terms of color and design.

2. Customization Features

Diverse Effects: Supports multiple fluorescent colors and pattern combinations to meet brand-specific needs.

Invisible Protection: Fluorescent patterns are invisible under normal light and require UV light for verification.

Printing Compatibility: Can be integrated with various printing techniques (e.g., offset, gravure) for diverse products.

3. Applications

Customized UV fluorescence is commonly used in currency, tickets, identification documents, and product packaging. For example, brands can create labels that reveal logos under UV light for rapid authenticity verification.

V. Comprehensive Advantages of Customized Printing Anti-Counterfeiting Technologies

1. Enhancing Brand Image

Through customized holographic patterns, security designs, watermarks, and UV fluorescence, brands can showcase unique design aesthetics, boosting consumer recognition and trust.

2. Strengthening Anti-Counterfeiting Capabilities

These technologies, combined with high-precision printing and complex processes, significantly increase the difficulty of replication. Multi-layered anti-counterfeiting designs (e.g., holograms + watermarks + fluorescence) further enhance security.

3. Flexibility and Adaptability

Customized printing technologies support various substrates and printing methods, accommodating products from paper to plastic. Brands can choose single or combined technologies based on budget and security needs.

VI. Trends and Future Outlook

1. Integration with Digital Technologies

With the rise of QR codes, NFC chips, and other technologies, customized printing anti-counterfeiting is increasingly integrated with digital verification. For example, combining UV fluorescent labels with QR code scanning enables dual online-offline authentication.

2. Smart Material Applications

The adoption of nanotechnology and smart fluorescent materials is enhancing the precision and concealment of customized holograms and fluorescent anti-counterfeiting.

3. Green Printing

The use of eco-friendly fluorescent inks and sustainable substrates aligns customized anti-counterfeiting printing with green development goals.

结论

Holographic hot stamping, security patterns, watermarks, and UV fluorescence anti-counterfeiting technologies, through customized printing, offer efficient and personalized solutions for brand and product protection. These technologies enhance both security and aesthetics while strengthening brand competitiveness. Looking ahead, the integration of new materials and digital technologies will drive customized printing anti-counterfeiting toward smarter, more sustainable solutions.